LiteWIRE

Plastic fiber cables

Advantages of plastic optical fiber

- like any fiber, it just carries light no electricity: it is an electrical insulator, prevents the risk of electrical shock for installers and users, eliminates groud loops and all electromagnetic interferences, it can be run in the same conduits as electrical wires

- Easy to terminate and repair with basic electrician’s tools (watch video )

- Devices for plastic fiber use visible light (LED), no LASER: this means you can see the light coming out of the cable safely (no instruments needed)

- Fiber diameter is 1mm (much thicker than glass fibers)

- Fiber tip and connectors can be touched and work also if humid or wet.

- insensitive to vibrations (so no false alarms) in sensor applications, such as for the protection of air vents.

Attenuation of plastic fiber

A luminous signal transmitted over an optical fiber undergoes three types of attanuation, which result in a loss of power:

- attenuation of the material the fiber is made of.

- attenuation depending on affixing elements of Naria Security, which are essential for the system to work correctly (eg. tensioning bolts), and on elements for possible reparations

- attenuation depending on preventable external factors, like stresses due to tight curves of the fiber, overtightened cable ties, wrong positioned bolts, over-pulled fiber, etc. (see installation advices)

The systems of Naria Security already take into account the first two causes of attenuation and they also have a margin to compensate part of installation factors.

Machine maintenance with plastic fiber? Contact us!

Plastic fiber optic cables have been employed in industrial machinery for data transmission for several years. When a cable breaks, this can stop a machine and production activities, resulting in heavy economic loss. For this reason, it is necessary to replace it promptly.

Our LiteWIRE plastic fiber optic cable meets the standards required for the cables normally used to transmit data, also inside machines. As cable manufacturers, we are able ship cable spare parts within 24 hours using the fastest and most reliable couriers. If a We can also ship a patch cable terminated with connectors within a few days, depending on the type of connector required.

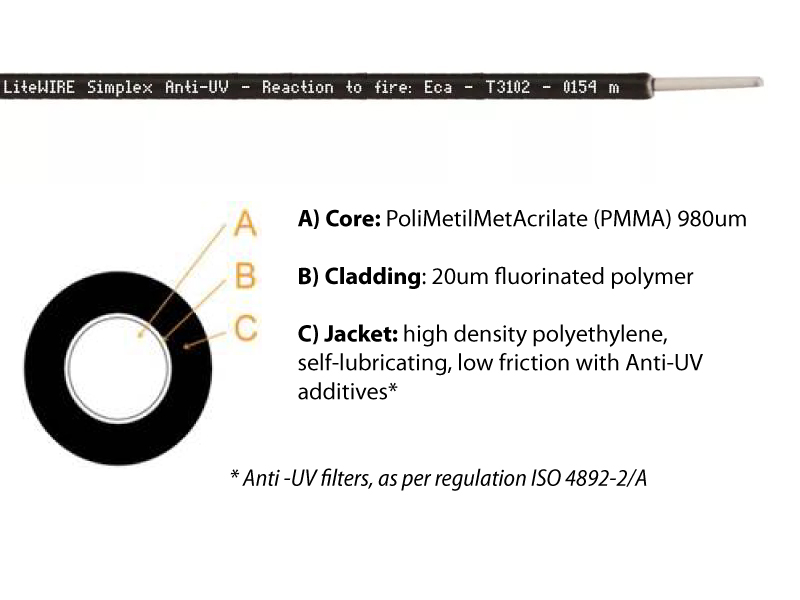

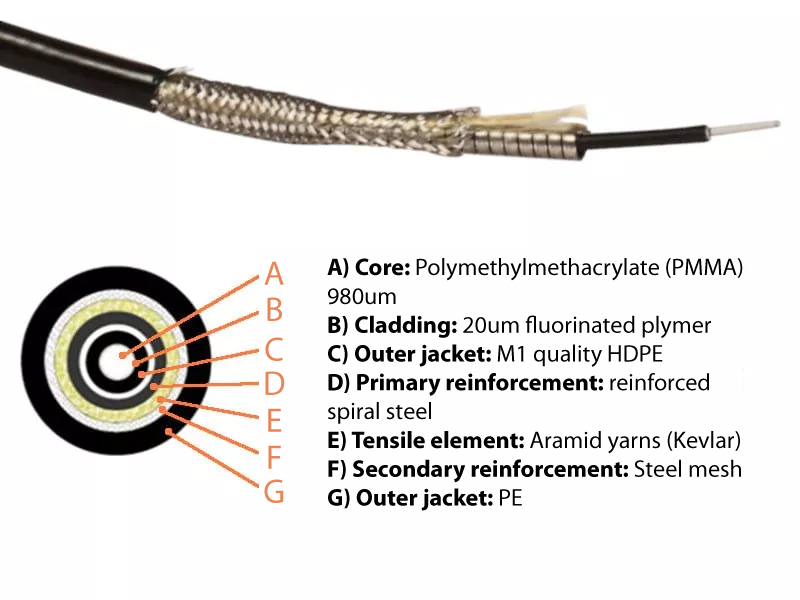

Our LiteWIRE plastic fiber cable has a jacket containing specific anti-UV filters, which make it resistant to sunlight and suitable for outdoors. LiteWIRE plastic fiber cable is made in Italy according to highest quality standards, which make it possible to transmit data up to a distance of 300m. We can also supply a plastic fiber optic cable with anti-rodent steel armour, and, on request, fiber cables with a jacket that is more resistant to industrial oils or hydrocarbons.

- Example: Attenuation of fiber installed on a flexible fence (LiteFENCE solution)

Let us consider an installation on a flexible fence which requires a LiteFENCE analyser, some tensioning bolts, plastic fiber cable LiteWIRE and cable ties.

The attenuation fo the luminous signal is measured in dB:

- the attenuation of the plastic fiber cable LiteWIRE, if placed correctly, is 1dB for 10m

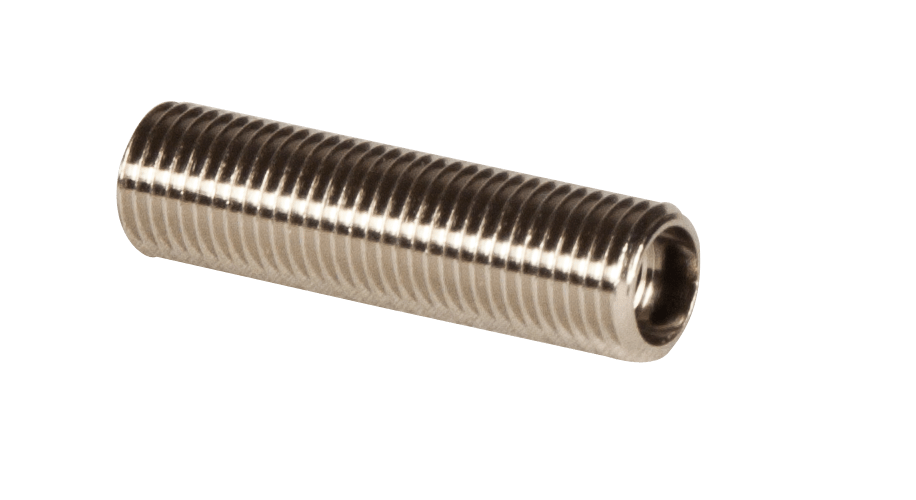

- a tensioning bolt has an attenuation of 0.1 dB (max 0.2dB) and must be placed 1 every 10m of plastic fiber cable.

The LiteFENCE analyser can manage an attenuatio up to 31 dB. For this reason, 250m of fiber (with max. attenuation of 25dB) are normally used with 25 tensioning bolts (attenuation from 2.5 dB to 5 dB max.)

The devices which can detect the variation of light, like LiteFENCE and LiteCOPPER (and LiteSUN Plus, on request) , have a built-in fuction which measure the loss of optical power: the power meter. This allows to keep the attenuation monitored during the installation and to detect any possible mistakes during installation

Order according to your needs

- LiteWIRE Simplex anti-UV, sunlight resistant

the most used cable, suitable for outdoor installations

the most used cable, suitable for outdoor installationsLEA1100B022M: per meter

LPL1025P022M: 250m spool

LPL1050P022M: 500m spool

LPL1100P022M: 1000m spool - LiteWIRE Simplex anti-rodent

with double steel armouring (mechanical and anti-rodent protection)

with double steel armouring (mechanical and anti-rodent protection)KEY0500B050P: 500m spool.

KEY0250B050P: 250m spool.

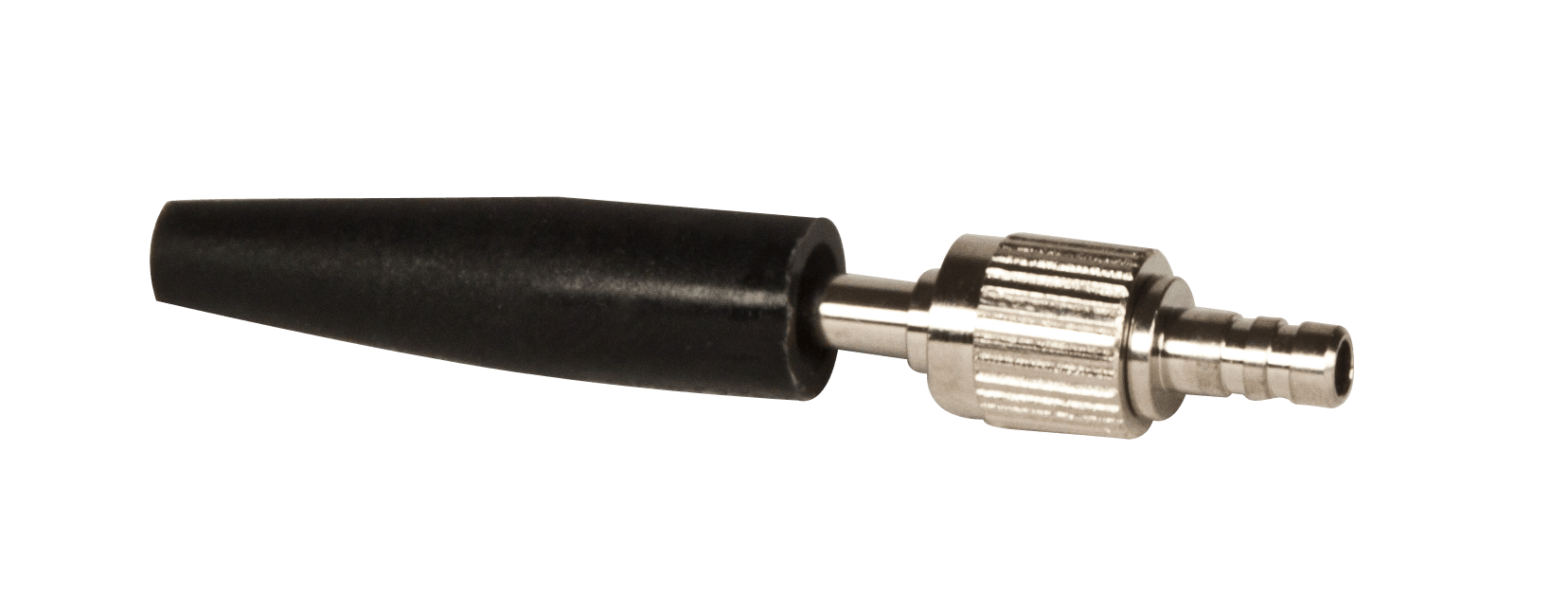

KEY1100B050P: per meter (in multiples of 50m) - FSMA terminated patches of LiteWIRE Simplex with double armouring

Patch-cord of plastic fiber LiteWIRE with double anti-rodent armouring, terminated with FSMA connectors. More patches can be connected to each other with a coupler.

Patch-cord of plastic fiber LiteWIRE with double anti-rodent armouring, terminated with FSMA connectors. More patches can be connected to each other with a coupler.PATC000N005A, 5m

PATC000N010A, 10m

PATC000N015A, 15m

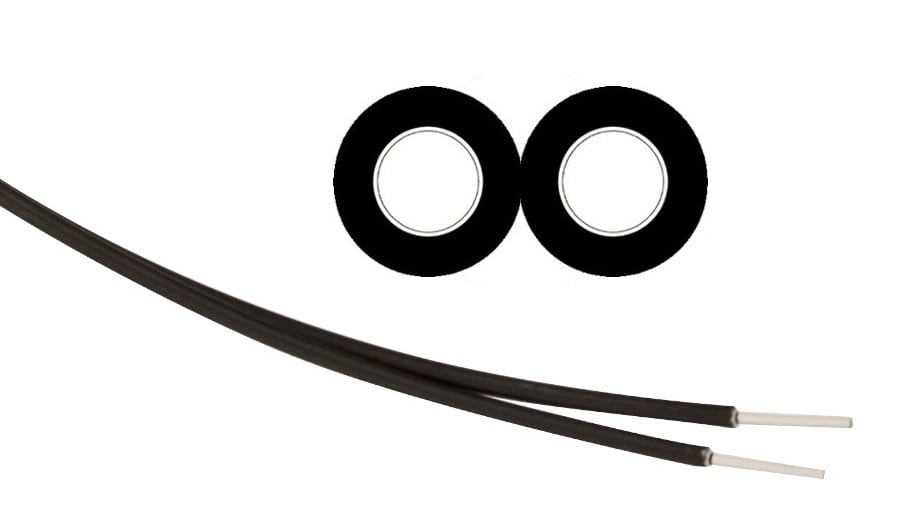

PATC000N020A, 20m - LiteWIRE Duplex anti-UV

Duplex plastic fiber cable (i.e. a zip with two fibers), used with Ethernet signal converters

Duplex plastic fiber cable (i.e. a zip with two fibers), used with Ethernet signal convertersTOL2025V044P: 250m spool

TOL2050V044P: 500m spool

TOL2100V044P: 1000m spool - Accessories

SMAC001M022M. FSMA connectors (1 pack= 10pcs.)

SMAC001M022M. FSMA connectors (1 pack= 10pcs.)

SMAA001M022M. Coupler. Every coupler requires two FSMA connectors.

SMAA001M022M. Coupler. Every coupler requires two FSMA connectors.

POLF100A000W. 5um sand paper

POLF100A000W. 5um sand paper

LiteWIRE termination and reparation kit, containing cutter, crimping tool, automatic cable stripper, 20 FSMA connectors, 2 couplers for reparations, polishing disc for FSMA, 5um sandpaper, 9x lens.